|

|

Technology: Online Oil Analysis

We are concerned about water & metal in the oil and not about comprehensive analysis.

|

When wear is occuring particle counters can show a trend often before the vibration has changed.

When the vibration changes, it indicates the source of the wear debris as a gear set or bearing.

Our choice is the inductive type, with a coil around a 4 mm dia ceramic cylinder, through which the oil flows, because they detect significant damage debris, and it is difficult to block them.

They are sensitive to Fe particles in 5 size ranges from 50 to 800+ um and non Fe particles in 5 size ranges from 150 to 1600+ um, which covers minor to major wear trending.

Rolling mill scale though Fe based is not conductive, and not detected, thus avoiding false data.

|

|

|

Water causes oil to loose itís lubricating ability even at low levels of relative humidity, and so reduces machine life span to a small fraction of normal. So especially if there is an oil / water heat exchanger, knowing relative humidity, RH, continuously is very useful.

This sensor reads 0 to 100% RH and temperature to 100 deg C which is appropriate for normal industrial gearboxes. Catching a leak early prevents needless wear.

|

|

|

In steel rolling mill applications water can enter the gearboxes via the rolling wheel labyrinth seals, and return oil water content greater than 100% RH is common. With a badly leaking seal, a particular gearbox may be returning 25% water to the main tank. This huge amount of water falls out of solution quickly and is drained from the bottom of the tank, but the remaining oil may have several % water long term and so reduces machine life span to a small fraction of normal. Centrifuging and/or vacuum dehydration are used to avoid throwing huge amounts of oil out.

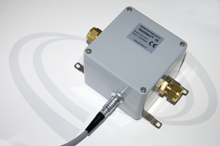

In these applications a sensor able to measure the whole range from 0% water in oil, to 0% oil in water is needed, and such a sensor is shown below. It measures capacitance between the outer tube and an inner one, and all water droplets from 1 molecule size and upward are included.

|

|

|